Water Industry Process Automation & Control

VEGA Controls are a family run instrumentation company run from their headquarters in Schiltach in Germany

At the centre of their philosophy they realise that production processes are becoming ever more complex. So it’s really important that the measurement technology is used to control and monitor the processes is all the more understandable and intuitive. VEGA has set itself the goal of developing innovative measurement technology that is easy to install and operate and offers maximum safety and reliability.

VEGA employs over 1,400 people worldwide, 660 of whom work at its headquarters in Schiltach in the Black Forest. This is where, for over 50 years, solutions to demanding measuring tasks are being conceived and brought to reality: for chemical and pharmaceutical plants, the food industry, drinking water supply systems, sewage treatment plants, landfills, mining, power generation, oil platforms, ships and aircraft.

VEGA is active in over 80 countries with its global network of subsidiaries and distributors. The company and its products have all the necessary certificates and approvals for worldwide application. This applies to the technical safety as well as the quality of the products and services.

Vega Control Systems

Kendal House,

Victoria Way

Burgess Hill,

West Sussex

RH15 9NF

United Kingdom

Tel.: +44 1444 870055

Fax: +44 1444 870080

info.uk@vega.com

VEGA's range of products for the Water Industry include their market leading range of radar level sensors amongst many other products. Within this range of products are. For more details see the catalogue link on the left

Company Showcase - Vega Control Systems

VEGAPULS WL61

VEGAPULS WL S61

VEGAPULSWL64

VEGAWELL52

VEGABAR 82

VEGAVIB 62

VEGAMET 391

VEGAMET 625

The VEGAPULS WL S 61 is the ideal sensor for all typical application in water and wastewater. It is particularly suitable for level measurement in the water processing, in pump stations and overflow basins. The flood-proof IP 68 housing of VEGAPULS WL S 61 ensures a maintenance-free continuous operation. With integrated Bluetooth for wireless communication via smartphone, tablet or PC.

The sensor emits extremely short microwave pulses through the antenna. The emitted signal is reflected by the medium and received as an echo by the antenna.

The time between the emitted and received signal is proportional to the distance and depends from the filling height. The determined filling height is converted into a respective output signal and outputted as a measured value.

The sensor has a 8m range with an accuracy of +/- 5mm. It is loop powered with a 12m cable length and so is suitable for most of applications. It is programmable using bluetooth for ease of application.

VEGAPULS WL S61

Level Measurement

VEGAPULS WL61

Flow & Level Measurement

The Vegapuls WL61 was the first and is the only level meter certified under the MCERTS Scheme for measurement of open channel flow.

The VEGAPULS WL 61 is available with MCERTS for open channel flow measurement as part of a system with the VEGAMET 391 flow computer. If you want accurate flow measurement and metering unaffected by heavy condensation on a misty morning, gale force winds with loss of echo, or suffer temperature drift on a bright sunny day

The WL series radars are ruggedly designed for the water industry with IP68 (2 Bar/20m submersible) housings and fully encapsulated antennas. They meet the Level Probing Radar (LPR) EN standard approved for use outside. Their focused signal assures accurate measurement and monitoring. A range of mounting options enables easy deployment and installation. Powerful capability with internal 32 point and user defined flow curves means that it can also be used as a ‘compact’ open channel flow sensor.

VEGAPULS W64

Level Measurement

The VEGAPULS 64 is an 80Ghz radar designed for many applications in the Water Industry and with a 30m range and an accuracy of +/-1mm, it is a truly versatile instrument. With an 80-mm antenna, this results in a beam angle of only 3°. The radar level sensor receives only distinct, definitive reflections from the product surface. This makes the level measurement more accurate and reliable.

By comparison: ‘conventional’ radar level sensors with 26 GHz transmission frequency and an antenna of the same size has a beam angle of approximately 10°.Due to the considerably narrower signal beam with 80GHz sensors, agitators, pumps, fittings or build-up on the vessel wall won’t be detected or cause interference that can affect the level control.

The antenna system of VEGAPULS 64 is encapsulated in PTFE or PEEK, so there are no cavities or crevices in which product can accumulate. The surface of the material is very finely processed with diamond tools, which also considerably reduces product adhesion. In addition, special software algorithms filter out interference caused by build up on the antenna system. Thanks to the high dynamic range of the sensor, signal attenuation caused by product deposits is largely compensated. This allows the level to be reliably detected even with contamination on the sensor.

VEGAPULS radar has a wide offering of process fittings ranging from ¾” BSP up to DN 80, as shown on the left

VEGAWELL 52

Submersible Pressure Transmitters

The VEGAWELL 52 is a submersible pressure transmitter for gauge measurement in water and wastewater. This hydrostatic absolute pressure transmitter with ceramic measuring cell for continuous level measurement for monitoring and control tasks, e.g.

- flow measurement i.e. overflow measurement on weirs

- water level measurement for control of groundwater pumps

- level measurement of tanks with top mounting

Its unique flush mounting, high purity and extremely robust sensing diaphragm offer real benefits for the customer resulting in long sensor life with minimal maintenance or recalibration.

- No drift, long-term stability

- No clogging

- High overload

- Extremely abrasion resistant

- Integrated Lighting protection

It has integrated lighting protection with a measuring range of 600m or 60 bar and at the heart of the instrument has a ceramic CERTEC® measuring cell. Its is EXTREMELY robust and almost drift free over its lifetime, due to the abrasion and overload resistant ceramic technology.

Principle of hydrostatic pressure measurement with CERTEC ceramic.

The liquid column causes a capacitance change in the measuring cell via minute deflection of the ceramic diaphragm (only 12µm = 0.012mm a human hair is 0.08mm). This change is converted into a standard 4 … 20 mA signal. The entire measuring cell consists of high purity ceramic and is characterised, apart from its excellent long-term material stability, by very high overload capability and its resistance to conditions like pressure shocks, pulsing and water hammer too.

VEGABAR 82

Pressure transmitter with ceramic measuring cell

The pressure transmitter VEGABAR 82 is the robust all-rounder with an innovative flush mounted hard wearing ceramic measuring cell that VEGA manufactures as a full-range supplier of pressure instrumentation.

The versatile standard instrument handles temperatures up to 150° C. Its extremely high overload factor of 200 is unique to the market. This pressure sensor covers 95% of all applications in the water industry, with its oil-free ceramic CERTEC® measuring cell.

Changing pressure causes a capacitance change in the measuring cell via minute deflection of the ceramic diaphragm (only 12µm = 0.012mm …a human hair is 0.080mm). This change is converted into a standard 4 … 20 mA signal.

The entire measuring cell consists of high purity ceramic and is characterised, apart from its excellent long-term material performance and overload capability it offers excellent resistance to conditions like pressure shocks, pulsing and water hammer too.

At the heart of the instrument has a ceramic CERTEC® measuring cell. Its is EXTREMELY robust and almost drift free over its lifetime, due to the abrasion and overload resistant ceramic technology. The measuring cell is flush mounted to avoid clogging, and it is extremely hard to eliminates abrasion damage and its uniquely patented ‘O’ ring sealing concept means that is also protected from abrasion too. It is also equipped with a temperature sensor, so the temperature value can be displayed via the indicating and adjustment module or output as a process value..

Connect any two of the VEGABAR 80 series sensors together (threaded, flanged or suspended) to get easy, reliable and low cost differential measurement across screens, filters and sand beds

-crop-u133283.jpg?crc=4172208287)

VEGAVIB 62

Vibrating Level Switch

The VEGAVIB 62 is a level switch for granular and coarse-grained bulk solids. The optimized rod design without corners and edges avoids jamming of the bulk solids and is easy to clean. The VEGAVIB 62 detects reliably and accurately the min. or max. limit level in bulk solids. The position of the switching point is specified flexibly through the length of the suspension cable.

The vibrating rod of VEGAVIB 62 is energized by a piezo drive to vibrate at its resonance frequency. If the medium covers the vibrating rod, the amplitude is damped. The electronics detects this change and converts it into a switching command. A reliable function in granulated bulk solids is ensured by the ideal rod design.

Designed to work granular and coarse-grained bulk solids. The optimized rod design without corners and edges avoids jamming of the bulk solids and is easy to clean. The VEGAVIB 62 detects reliably and accurately the min. or max. level in bulk solids it is ideal for working within grit and sludge tanks to indicate the minimum and maximum levels of solids within the process

VEGAMET 391

Signal Conditioner

Measured value indication, simple control functions, remote enquiry of measured data. optimized for water/sewage water industry

The VEGAMET 391 signal conditioning instrument powers the connected 4 … 20 mA/HART sensor, processes and displays the measured values. The VEGAMET 391 is ideal for simple control tasks in level, gauge and process pressure measurement as well as inventory management (VMI) and remote enquiry. Comprehensive adjustment functions allow individual adaptations to the respective application. In water/wastewater management, the instrument stands out with special functions such as pump switching, flow volume measurement, tendency functions and totalizer.

The VEGAMET 391 signal conditioning instrument powers any individual 4 … 20 mA/HART sensor and processes its measured value. Through an adjustment on VEGAMET, this measured value can be individually scaled/linearised and transferred to connected instruments via the current output. Six operating relays are available as limit alarms.

Optional interfaces offer the possibility of remote enquiry of measured values. With the built-in webserver, the measured values can be made available in a network.

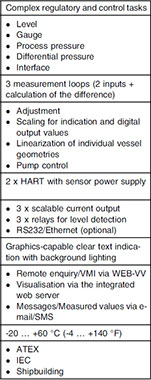

VEGAMET 625

Dual Channel Signal Conditioner

The VEGAMET 625 signal conditioning instrument powers the connected 4 … 20 mA/HART sensor, processes and displays the measured values received via HART multidrop. The VEGAMET 625 is ideal for simple control tasks in level, gauge, interface, differential and

process pressure measurement. For inventory management in remote storage silos, interfaces for remote data transmission are integrated.

Comprehensive adjustment functions allow individual adaptations to the respective application.

The VEGAMET 625 signal conditioning instrument powers two HART sensors and processes their measured values. Through an adjustment on the VEGAMET, these measured values can be individually scaled/linearised and transferred to downstream systems via the current outputs.

Beside the graphic-capable indication there are three operating relays that serve as limit alarms for control tasks. With instruments with optional interface, measured values can be retrieved via modem or network and indicated with the aid of a web browser or WEB-VV. In addition, it is possible to send a measured value or message via e-mail.

Site Map

Home

Industry News

Key Companies

Knowledge Management

WIPAC Monthly

What WIPAC Does

Industry Events

About WIPAC

Social Media and Supporting WIPAC

WIPAC on LinkedIn

WIPAC on Twitter

Patreon